Craven Lime Works & Hoffman Kiln

Scheduled Monument

Free to enter

Free Car park

Self Guided Trail

No other facilities

Grid Reference: SD 824 663

Situated off the B6479 about 3/4 mile north of Langcliffe village and adjacent to the Settle-Carlisle railway.

When level with the paper mill turn right up a lane leading under a railway bridge.

Follow the lane to a junction and go right to a signed car park.

The Craven Lime Works site is a stunning piece of industrial heritage with a real WOW factor

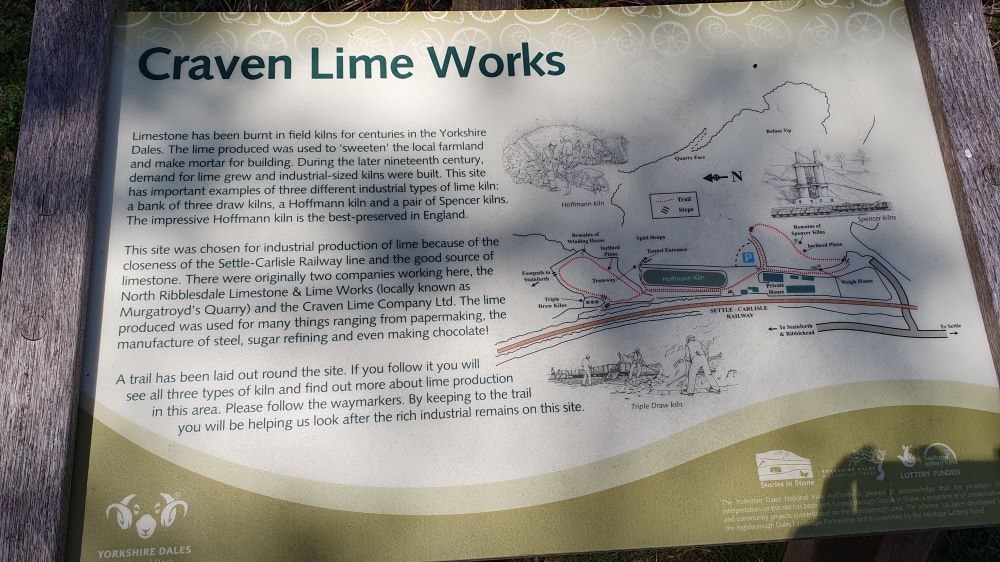

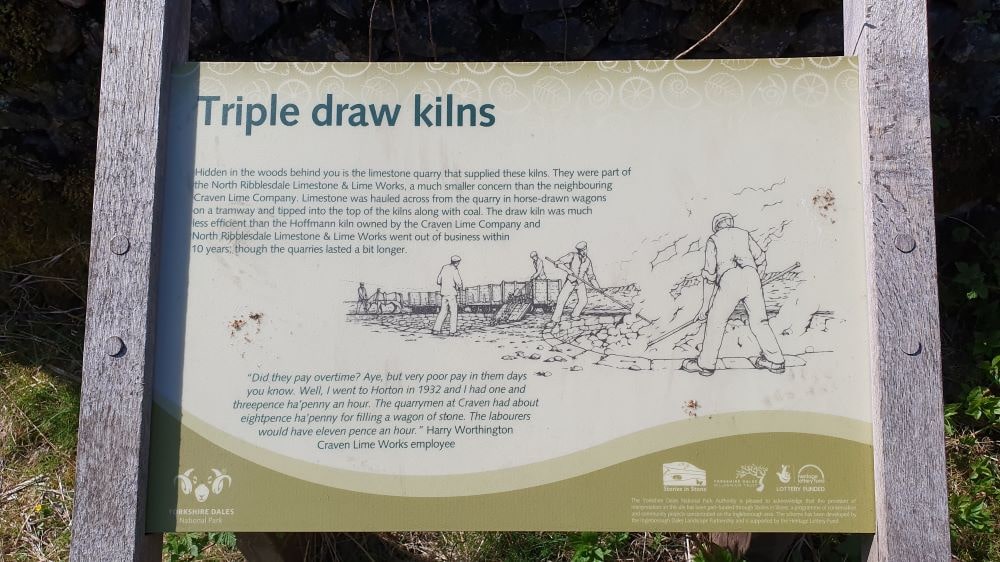

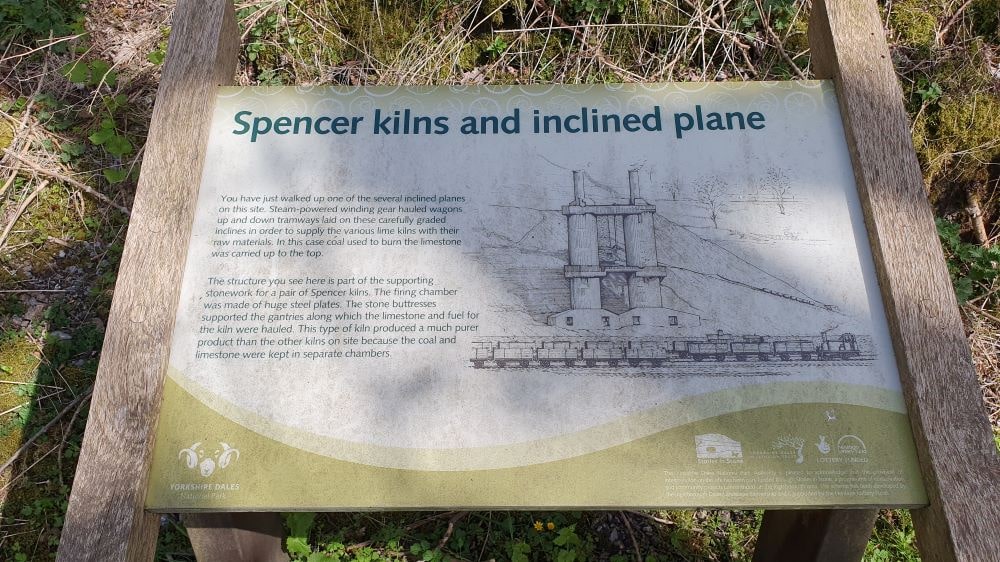

There are the remains of three types of Lime Kiln on the site; the Hoffman Kiln (definitely the star attraction!), Triple Draw Kilns and a Spencer Kilns

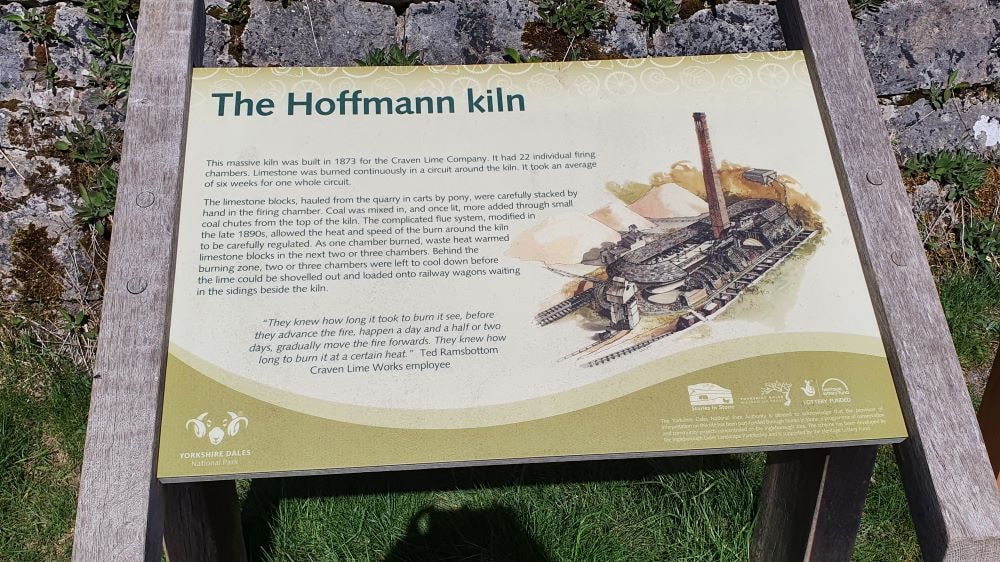

This industrial scale lime kiln was built in 1873 for the Craven Lime Company. The Hoffmann Continuous kiln was patented in 1858 by its German inventor Friedrich Hoffmann. The version built under licence at Langcliffe had 22 individual burning chambers. Limestone was burned continuously in a circuit around the kiln and it took an average of six weeks for one whole circuit.

Limestone blocks from the nearby quarry were barrowed in and carefully stacked by hand in the burning chamber. Coal was mixed in, and once lit, more added through small coal chutes from the top of the kiln. The complicated flue system allowed the heat and speed of the burn around the kiln to be carefully regulated. As one chamber burned, waste heat warmed limestone blocks in the next two or three chambers. Behind the burning zone, two or three chambers were left to cool down before the lime could be shovelled out and loaded onto railway wagons waiting in the sidings beside the kiln.

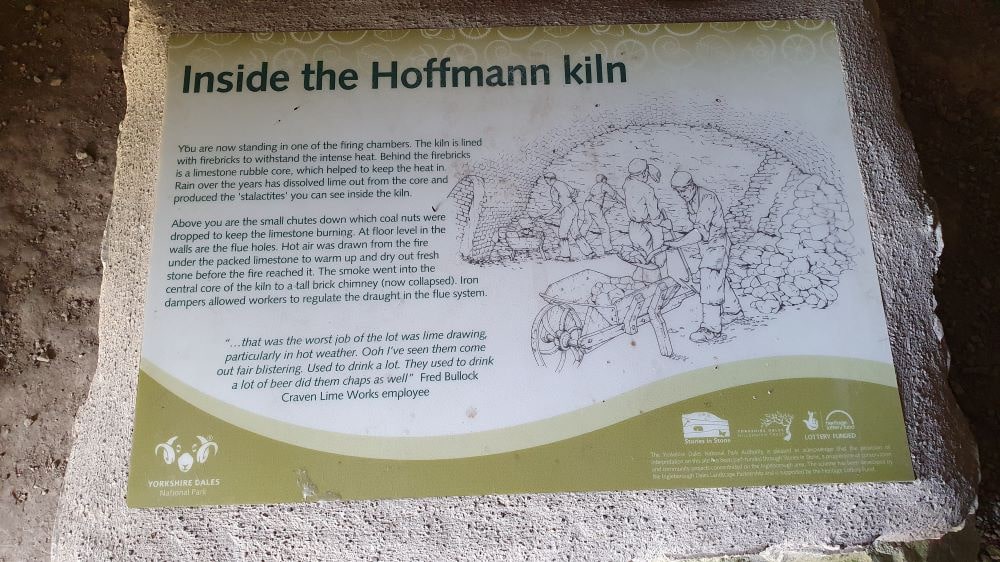

The kiln is lined with firebricks to withstand the intense heat. Behind the firebricks is a limestone rubble core, which helped to keep the heat in. In the roof are the small chutes down which crushed coal was dropped to keep the limestone burning. At floor level in the walls are the flue holes. Air was drawn from the outside under the burning limestone and the smoke went up the central core of the kiln to the chimney. Iron dampers on the roof allowed workers to regulate the draught in the flue system.

In 1931, competition from elsewhere and a general downturn in sales led to the closure of the Hoffmann kiln and its associated quarry at Langcliffe. The kiln was fired up one more time in 1937, but in 1939 it was closed down permanently. In 1951, arrangements had been made to ceremoniously demolish the chimney, but it came down of its own accord the day before with no one there to see it.

Source: Johnson, David (2002) Limestone Industries of the Yorkshire Dales. Stroud: Tempus